S系列非接触式密封件由带有径向循环槽的、磨削的、平面平行的钢环与其中装有的弹簧钢弹片做组成,并由脂垫(GN60)所包围。这些弹簧钢环片在安装时通过一个引导斜面压入与此适配的MD系列密封圈螺母的孔内,或者压入轴承座孔中并固定。

这时转动迷宫密封的配合在轴上的定距环(支撑环),相对环片而接触。槽中的脂垫防止环片轴向碰壁。通过这种方式预紧的在轴承附近设置的迷宫密封证明效果极佳(角接触球轴承和60°角接触球轴承)。

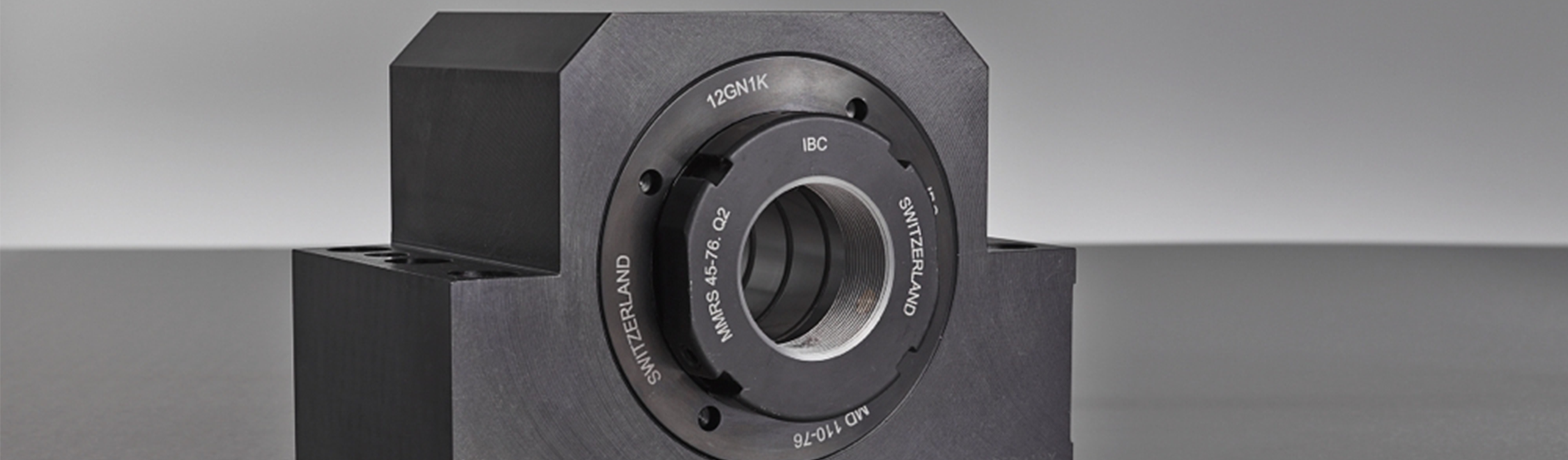

MD系列带有外螺纹的密封圈螺母也可用于固定轴承外圈或其他机械零件。他们需要粘结固定,也可作外部径向固定。

| 零件型号 | da (mm) | db (mm) | dc (mm) | B (mm) | E (mm) |

|---|---|---|---|---|---|

| S12-26 | 12 | 21 | 25.5 | 7 | 26 |

| S15-26 | 15 | 21 | 25.5 | 7 | 26 |

| S17-36 | 17 | 26 | 35.5 | 7 | 36 |

| S20-36 | 20 | 26 | 35.5 | 7 | 36 |

| S25-40 | 25 | 32 | 39.5 | 7 | 40 |

| S25-50 | 25 | 41 | 49.5 | 10 | 50 |

| S30-50 | 30 | 41 | 49.5 | 10 | 50 |

| S30-60 | 30 | 46 | 59.5 | 10 | 60 |

| S35-60 | 35 | 46 | 59.5 | 10 | 60 |

| S35-76 | 35 | 66 | 75.5 | 12 | 76 |

| S40-60 | 40 | 50 | 59.5 | 10 | 60 |

| S40-76-10 | 40 | 66 | 75.5 | 10 | 76 |

| S40-76 | 40 | 66 | 75.5 | 12 | 76 |

| S45-60 | 45 | 55 | 59.5 | 10 | 60 |

| S40-66 | 45 | 55 | 65.5 | 10 | 66 |

| S45-66 | 45 | 60 | 65.5 | 10 | 66 |

| S45-76 | 45 | 66 | 75.5 | 12 | 76 |

| S50-76-10 | 50 | 68 | 75.5 | 10 | 76 |

| S50-76 | 50 | 68 | 75.5 | 12 | 76 |

| S55-76-10 | 55 | 68 | 75.5 | 10 | 76 |

| S55-76 | 55 | 68 | 75.5 | 12 | 76 |

| S55-99 | 55 | 86 | 98.5 | 12 | 99 |

| S60-99 | 60 | 86 | 98.5 | 12 | 99 |

| S70-99 | 70 | 86 | 98.5 | 12 | 99 |

| S75-99 | 75 | 86 | 98.5 | 12 | 99 |

| S75-99-10 | 75 | 86 | 98.5 | 10 | 99 |

| S80-132 | 80 | 114 | 131.5 | 14 | 132 |

| S80-132-16 | 80 | 114 | 131.5 | 16 | 132 |

| S80-132-24 | 80 | 114 | 131.5 | 24 | 132 |

| S85-132 | 85 | 114 | 131.5 | 14 | 132 |

| S90-132 | 90 | 114 | 131.5 | 14 | 132 |

| S100-132 | 100 | 114 | 131.5 | 14 | 132 |

| S100-162 | 100 | 142 | 161.3 | 24 | 162 |

| S110-132 | 110 | 120 | 131.5 | 14 | 132 |

| S127-162 | 127 | 144 | 161.3 | 14.5 | 162 |

| 零件型号 | G 螺纹直径×螺距 | E (mm) | F (mm) | H (mm) | J (mm) | K (mm) | N (mm) | 容许轴向载荷 (kN) |

|---|---|---|---|---|---|---|---|---|

| MD 40-26 | M40×1.5P | 26 | 28 | 32 | 4.3 | 9 | 27 | 45 |

| MD 40-26 | M40×1.5P | 26 | 28 | 32 | 4.3 | 9 | 27 | 45 |

| MD 50-36 | M50×1.5P | 36 | 41 | 42.5 | 4.3 | 10 | 37.5 | 65 |

| MD 50-36 | M50×1.5P | 36 | 41 | 42.5 | 4.3 | 10 | 37.5 | 65 |

| MD 55-40 | M55×1.5P | 40 | 45 | 47 | 4.3 | 10 | 42 | 77 |

| MD 70-50 | M70×1.5P | 50 | 55 | 59.5 | 4.3 | 12 | 53.73 | 100 |

| MD 70-50 | M70×1.5P | 50 | 55 | 59.5 | 4.3 | 12 | 53.73 | 100 |

| MD 80-60 | M80×1.5P | 60 | 65 | 72 | 4.3 | 12 | 63 | 130 |

| MD 80-60 | M80×1.5P | 60 | 65 | 72 | 4.3 | 12 | 63 | 130 |

| MD 110-76 | M110×2.0P | 76 | 92 | 90 | 6.3 | 14 | 79.5 | 190 |

| MD 80-60 | M80×2.0P | 60 | 65 | 72 | 4.3 | 12 | 63 | 130 |

| MD 95-76 | M95×2.0P | 76 | 82 | 84.5 | 4.3 | 12 | 79.5 | 150 |

| MD 110-76 | M110×2.0P | 76 | 92 | 90 | 6.3 | 14 | 79.5 | 190 |

| MD 80-60 | M80×1.5P | 60 | 65 | 72 | 4.3 | 12 | 63 | 130 |

| MD 85-66 | M85×1.5P | 66 | 72 | 76 | 4.3 | 12 | 69 | 130 |

| MD 85-66 | M85×1.5P | 66 | 72 | 76 | 4.3 | 12 | 69 | 130 |

| MD 110-76 | M110×2.0P | 76 | 92 | 90 | 6.3 | 14 | 79.5 | 190 |

| MD 95-76 | M95×2.0P | 76 | 82 | 84.5 | 4.3 | 12 | 79.5 | 150 |

| MD 110-76 | M110×2.0P | 76 | 92 | 90 | 6.3 | 14 | 79.5 | 190 |

| MD 95-76 | M95×2.0P | 76 | 82 | 84.5 | 4.3 | 12 | 79.5 | 150 |

| MD 95-76 | M95×2.0P | 76 | 82 | 84.5 | 4.3 | 12 | 79.5 | 150 |

| MD 130-99 | M130×2.0P | 99 | 110 | 112 | 6.3 | 14 | 103 | 220 |

| MD 130-99 | M130×2.0P | 99 | 110 | 112 | 6.3 | 14 | 103 | 220 |

| MD 130-99 | M130×2.0P | 99 | 110 | 112 | 6.3 | 14 | 103 | 220 |

| MD 120-99 | M120×2.0P | 99 | 101 | 112 | 6.3 | 14 | 103 | 210 |

| MD 120-99 | M120×2.0P | 99 | 101 | 112 | 6.3 | 14 | 103 | 210 |

| MD 175-132 | M175×3.0P | 132 | 147 | 153 | 8.3 | 24 | 137.3 | 495 |

| MD 175-132 | M175×3.0P | 132 | 147 | 153 | 8.3 | 24 | 137.3 | 495 |

| MD 175-132 | M175×3.0P | 132 | 147 | 153 | 8.3 | 24 | 137.3 | 495 |

| MD 175-132 | M175×3.0P | 132 | 147 | 153 | 8.3 | 24 | 137.3 | 495 |

| MD 175-132 | M175×3.0P | 132 | 147 | 153 | 8.3 | 24 | 137.3 | 495 |

| MD 160-132 | M160×3.0P | 132 | 134 | 148 | 6.3 | 18 | 137.3 | 340 |

| MD 220-162 | M220×3.0P | 162 | 172 | 190 | 10.3 | 24 | 170 | 620 |

| MD 160-132 | M160×3.0P | 132 | 134 | 148 | 6.3 | 18 | 137.3 | 340 |

| MD 190-162 | M190×3.0P | 162 | 167 | 176 | 6.3 | 18 | 166 | 440 |