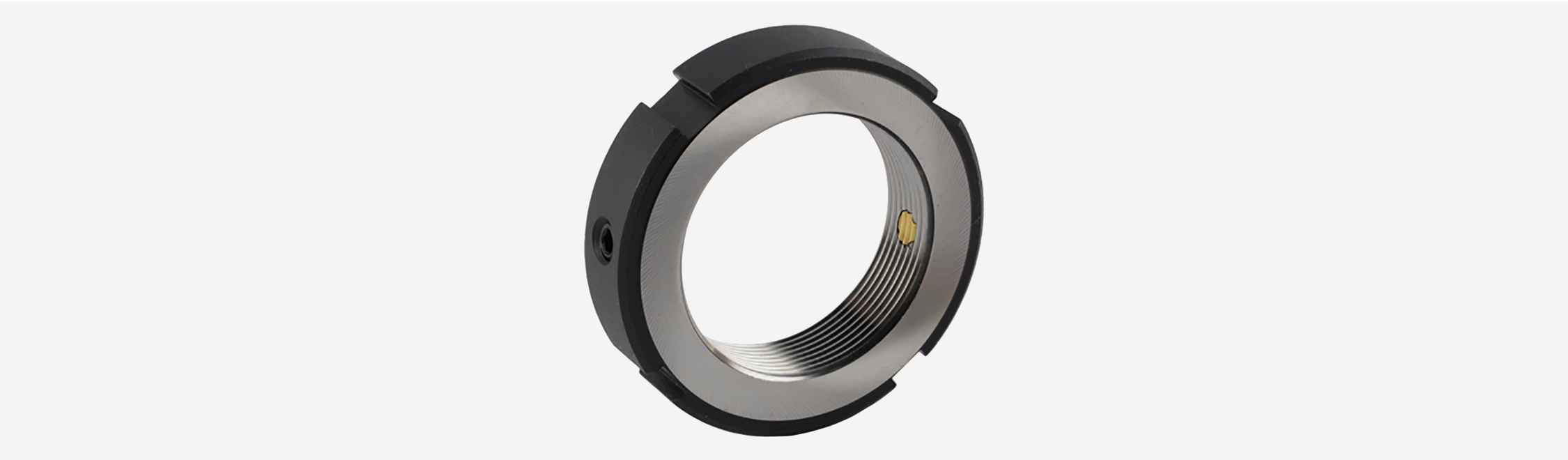

日本FKD公司生产的ZM系列径向锁定螺母,其螺纹面和端面同时磨削加工完成,并控制两个紧定螺钉的角度为180°或60°(型号末尾标记S,例ZM30S)。 此外,螺母工作面已经过抛光处理,提高了表面光亮度,增强了产品的使用性能。

- 本体材质:SCM435(35CrMo)

- 表面处理:黑色涂层处理

- 调质硬度:M85以下规格 HRC30°~37°;M90以上规格HRC15°~20°

- 螺纹精度:ISO-4H

- 直角度:0.002~0.005mm

| 零件型号 | d 螺纹直径×螺距 | D (mm) | h (mm) | g (mm) | t (mm) | d1 (mm) | c (mm) | 紧定螺钉 | 螺钉扭紧力矩 (Nm) | 直角度 (mm) |

|---|---|---|---|---|---|---|---|---|---|---|

| ZM6 | M6×0.5P | 16 | 8 | 3 | 2 | 12 | 4 | M 4 | 2 | 0.002 |

| ZM8 | M8×0.75P | 16 | 8 | 3 | 2 | 11 | 4 | M 4 | 2 | 0.002 |

| ZM10 | M10×0.75P | 18 | 8 | 3 | 2 | 13 | 4 | M 4 | 2 | 0.002 |

| ZM10 | M10×1.0P | 18 | 8 | 3 | 2 | 13 | 4 | M 4 | 2 | 0.002 |

| ZM12 | M12×1.0P | 22 | 8 | 3 | 2 | 18 | 4 | M 4 | 2 | 0.002 |

| ZM15 | M15×1.0P | 25 | 8 | 3 | 2 | 21 | 4 | M 4 | 2 | 0.002 |

| ZM17 | M17×1.0P | 28 | 10 | 4 | 2 | 23 | 5 | M 5 | 3.5 | 0.002 |

| ZM20 | M20×1.0P | 32 | 10 | 4 | 2 | 27 | 5 | M 5 | 3.5 | 0.002 |

| ZM25A | M25×1.5P | 40 | 12 | 5 | 2 | 33 | 6 | M 6 | 7 | 0.003 |

| ZM30 | M30×1.5P | 45 | 12 | 5 | 2 | 40 | 6 | M 6 | 7 | 0.003 |

| ZM35 | M35×1.5P | 52 | 12 | 5 | 2 | 47 | 6 | M 6 | 7 | 0.003 |

| ZM40 | M40×1.5P | 58 | 14 | 6 | 2.5 | 52 | 7 | M 6 | 7 | 0.003 |

| ZM45 | M45×1.5P | 65 | 14 | 6 | 2.5 | 59 | 7 | M 6 | 7 | 0.003 |

| ZM50 | M50×1.5P | 70 | 14 | 6 | 2.5 | 64 | 7 | M 6 | 7 | 0.003 |

| ZM55 | M55×2.0P | 75 | 16 | 7 | 3 | 68 | 8 | M 6 | 7 | 0.005 |

| ZM60 | M60×2.0P | 80 | 16 | 7 | 3 | 73 | 8 | M 6 | 7 | 0.005 |

| ZM65 | M65×2.0P | 85 | 16 | 7 | 3 | 78 | 8 | M 6 | 7 | 0.005 |

| ZM70 | M70×2.0P | 92 | 18 | 8 | 3.5 | 85 | 9 | M 8 | 16.5 | 0.005 |

| ZM75 | M75×2.0P | 98 | 18 | 8 | 3.5 | 90 | 9 | M 8 | 16.5 | 0.005 |

| ZM80 | M80×2.0P | 105 | 18 | 8 | 3.5 | 95 | 9 | M 8 | 16.5 | 0.005 |

| ZM85 | M85×2.0P | 110 | 18 | 8 | 3.5 | 102 | 9 | M 8 | 16.5 | 0.005 |

| ZM90 | M90×2.0P | 120 | 20 | 10 | 4 | 108 | 10 | M 8 | 16.5 | 0.005 |

| ZM95 | M95×2.0P | 125 | 20 | 10 | 4 | 113 | 10 | M 8 | 16.5 | 0.005 |

| ZM100 | M100×2.0P | 130 | 20 | 10 | 4 | 120 | 10 | M 8 | 16.5 | 0.005 |

| ZM105 | M105×2.0P | 140 | 22 | 12 | 5 | 126 | 11 | M10 | 30 | 0.005 |

| ZM110 | M110×2.0P | 145 | 22 | 12 | 5 | 133 | 11 | M10 | 30 | 0.005 |

| ZM115 | M115×2.0P | 150 | 22 | 12 | 5 | 137 | 11 | M10 | 30 | 0.005 |

| ZM120 | M120×2.0P | 155 | 24 | 12 | 5 | 138 | 12 | M10 | 30 | 0.005 |

| ZM125 | M125×2.0P | 160 | 24 | 12 | 5 | 148 | 12 | M10 | 30 | 0.005 |

| ZM130 | M130×2.0P | 165 | 24 | 12 | 5 | 149 | 12 | M10 | 30 | 0.005 |

| ZM135 | M135×2.0P | 175 | 26 | 14 | 6 | 160 | 13 | M12 | 56 | 0.005 |

| ZM140 | M140×2.0P | 180 | 26 | 14 | 6 | 160 | 13 | M12 | 56 | 0.005 |

| ZM145 | M145×2.0P | 190 | 26 | 14 | 6 | 172 | 13 | M12 | 56 | 0.005 |

| ZM150 | M150×2.0P | 195 | 26 | 14 | 6 | 171 | 13 | M12 | 56 | 0.005 |

| ZM155 | M155×3.0P | 200 | 28 | 16 | 7 | 182 | 14 | M12 | 56 | 0.005 |

| ZM160 | M160×3.0P | 210 | 28 | 16 | 7 | 182 | 14 | M12 | 56 | 0.005 |

| ZM165 | M165×3.0P | 210 | 28 | 16 | 7 | 193 | 14 | M12 | 56 | 0.005 |

| ZM170 | M170 ×3.0P | 220 | 28 | 16 | 7 | 193 | 14 | M12 | 56 | 0.005 |

| ZM180 | M180×3.0P | 230 | 30 | 18 | 8 | 203 | 15 | M12 | 56 | 0.005 |

| ZM190 | M190×3.0P | 240 | 30 | 18 | 8 | 214 | 15 | M12 | 56 | 0.005 |

| ZM200 | M200×3.0P | 250 | 32 | 18 | 8 | 226 | 16 | M12 | 56 | 0.005 |

免责声明:本网站所有资源仅供参考学习,禁止未经授权的商业用途,如因依赖从本网站获得的信息并用于商业用途造成的损失,我们对此不负任何责任。